Ultracentrifugation

Location: U3202 MRB3

The CDB Equipment Resource maintains two ultracentrifuges. When the CDB core’s ultras are down, the VBI Equipment Core has backups available.

All ultracentrifuge users must receive MANDATORY training from the Equipment and Resource Manager in order to user any rotor or ultracentrifuge. This is regardless of previous experience.

Only CDB and VBI rotors are to be used in CDB and VBI centrifuges and vise versa as our service contract covers both rotor and centrifuge.

Below are helpful tools and usage notes which are great references for new users. The guide is a great reference for anyone who wants to verify that they are using the resource properly.

*PLEASE NOTE: IF YOU ARE RESERVING ONE OF THE TWO FLOOR ULTRACENTRIFUGES, YOU MUST DO TWO THINGS:

- You must type the rotor you intend to use into the notes section of the reservation.

- You must look at both ultracentrifuge calendars to see if the rotor you intend to use has not already been reserved.

ROTORS AND TUBES: Beckman Guide

ROTORS AND TUBES: Thermo-Sorvall Guide

Manuals provide specific information for each rotor, including

special operating procedures and precautions; tube, bottle, and adapter part numbers.

Spinning Virus?

If you are spinning any virus, you are required to decontaminate the rotor or swinging buckets once your centrifugation run is complete. You should be using an anti-viral product such as Enviricide (see link below). It is commonly known that 10% bleach is adequate for killing viruses. However, bleach is highly corrosive to metals (i.e., stainless steel, aluminum, copper, brass). If this is not clear or you have questions, please contact the Equipment Manager.

Floor Model Ultracentrifuges (One in CDB and one in VBI)

Tabletop model Ultracentrifuge

Online Rotor Calculation Tool

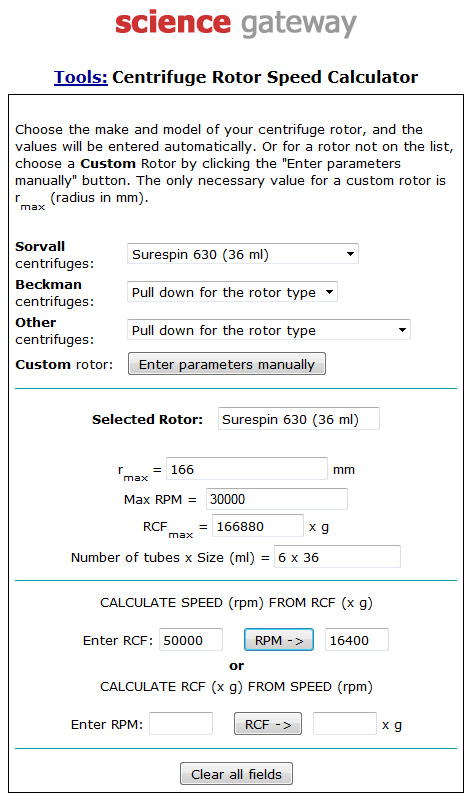

There are several online tools for converting rotations-per-minute (rpm) to relative-centrifugal-force (rcf or “x g”) or vice versa. These are extremely useful when you find a protocol where you know the parameters for centrifugation using a specific rotor but don’t have access to that rotor. In this case, you will need to utilize a tool which can help you “reverse calculate” these parameters. Science Gateway has a wide variety of rotor choices from which you can select to help you with this (see instructions and example below). Beckman has their own Rotor Calculator limited to their products which you can find HERE.

- Go to the link Science Gateway Rotor Calculator

- Select your rotor in the dropdown (i.e., Beckman, Sorvall, or Other)

- Type in your “x g” into the rcf box and hit the rpm button to calculate the rotations-per-minute needed to obtain that g force

- Sometimes published protocols are incomplete and the authors only publish the rpm for their rotor. You can always do the calculation in reverse by putting this in the rpm box and hit the rcf button to calculate the g force they obtained. Then, you would go to the previous step to recalculate the parameters for your particular rotor.

General usage notes for ultracentrifuges and rotors

- Rinse rotors with deionized water after use and dry upside down.

Why: The biggest problem a rotor will encounter is not being cleaned after use. Ionic solutions (i.e. bacterial media and cesium salts) will corrode aluminum rotors. Even the titanium ultraspeed rotors (like the Beckman 45 Ti) have aluminum lids and tops which can corrode.

- Always balance rotor tubes to the nearest 1/100 on a balance or scale. Do not balance tubes by eye. Specifically do not balance bacterial growth media for cell pelleting by eye.

Why: Your eye is highly sophisticated, but it is not an analytic measurement device capable of discriminating fractions of a gram. Even small imbalances are harmful to the ultraspeed floor model centrifuges. In large tubes, very small differences in solution height can have very different liquid masses. Also, tubes and adapters have similar, but not identical masses. You may safely assume the buckets of any rotor are balanced if they are put in correct swing slot.

- Humidity is the enemy of centrifuges.

Why: Humidity causes condensation on the cool lining of a centrifuge. This additional thermal mass makes temperature adjustment less efficient.

- Rotor well adapters should be removed after every run.

Why: Because small amounts of sample will collect at the bottom of the well in between the adapters and the rotor. One technician told me that the worst corrosion he sees is caused by never checking under the adapters.

- Always use a cart to move rotors.

Why: So you don’t drop the rotor, hurting it, yourself, your experiment, or someone else.

Important Notes about Tube Cleaning, Sterilization, and Reuse

If tubes are to be reused, special care must be taken during cleaning and sterilization. All tubes can be washed by hand with a mild detergent such as Solution 555 diluted 5-to-1 or 10-to-1 with water. This is particularly important for polycarbonate tubes and bottles which should not be exposed to a detergent with a pH higher than 8. Tubes and bottles should not be washed in commercial dishwashers as the detergents and high temperatures are too harsh. Solvents such as alcohol or acetone react unfavorably with many tube materials. If an organic solvent must be used in the cleaning procedure, consult bulletin IN-175 for a table of tube material/solvent compatibilities (or review the same document on the Beckman Coulter web site at www.beckmanbuilt.com.

The method chosen for sterilization has direct bearing on the number of reuses one can expect from a tube. Tubes and bottles of polyallomer, polyethylene, and glass can all be autoclaved, although in general, cold sterilization methods are not as harsh as autoclaving. Cold sterilization is recommended for both polycarbonate and Ultra-Clear. Do not dry tubes, bottles, or accessories in an oven. Labware should be air dried.

OptiSeal, Quick-Seal, Ultra Clear, and thinwall polyallomer tubes are intended for one-time use and should be discarded after use.

If maximum reuse is a major consideration, either polyallomer (preferably thick-walled) or polycarbonate tubes and bottles should be selected, and cold sterilization methods used. If these tubes are run completely filled in swinging bucket rotors, most of them can be reused a number of times. Chances of permanent deformation will be greater whenever the tubes are run in fixed angle rotors, without caps, and/or partially filled. All of these con ditions tend to stress the centripetal edge of the tube unduly. All tubes that have been used or autoclaved previously must be individually examined for signs of deformation or cracking before using them again.

Suggested Reading

If you want to know everything about using density gradients, I highly recommend Hinton & Dobrota “Density Gradient Centrifugation” in Laboratory Techniques in Biochemistry and Molecular Biology Volume 6, edited by Work & Work, 1-290. Amsterdam: North-Holland, 1978.