Enabling Technologies

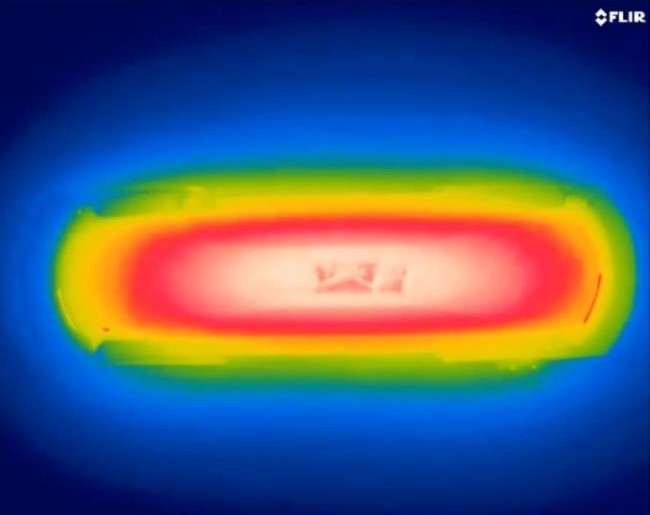

Our mission is to build a world we can trust by doing experiments at a realistic scale to translate discoveries into high impact research applications. We combine powerful modeling and simulation tools and sophisticated sensing and control techniques with risk and reliability analytics to improve the performance and reliability of systems in energy, security, and manufacturing applications. By looking at problems differently and changing the paradigm, we are working with our corporate, government, and academic partners to invent new technologies for ensuring that the world we build is reliable, safe and sustainable. For example, can we understand how a polymer cures through the lens of an infrared camera to reveal if the material is forming flaws when it is first constructed? And, if so, can we correct the way the material is curing before the flaws ever form in the first place? Read about our work in advanced composite materials as a supporting partner in the national composites institute.

Risk & Reliability Analytics

We develop a wide range of techniques for analyzing and predicting measures of risk and reliability of materials, structures and machines at all scales of the system. Our work touches on the fields of big data science and engineering as well as cyber-physical systems and human factors and has strong interdisciplinary dimensions. By measuring the current state of a system, like a rechargeable battery electrode, we can predict the reliability of that system even when it is damaged such as when the electrode is found to have impurities due to air bubbles, scratches or other such variations.

http://www.reliability-studies.vanderbilt.edu

Sensing & Controls

We develop new ways to sense materials and machines and we study nonlinear signatures to characterize system health. Our work also aims to support process and control decision making in a range of applications from energy to aerospace to manufacturing systems to improve performance, energy efficiency, reliability and cost metrics. For example, we developed smart blade technology to monitor wind turbines for damage and control the direction they point to reduce the damage caused by undesirable cyclic loading. This problem is especially challenging in wind farms, the productivity and reliability of which can be significantly effected by wake effect interactions.

Modeling & Simulation

We develop a wide range models that describe how the physical behavior of systems change as they degrade so that we can use these models to anticipate and prevent failure. Our models are both data-driven, to account for real-time information from sensor measurements, and physics-based, to incorporate our understanding of the system and its operating environment. For example, we developed a structural dynamic model to estimate the tip deflection of a wind turbine blade to detect when the composite material inside the blade was damaged. These models were enhanced based on experimental data that accurately captured the modes of vibration of the blades.